Exploring Deep Etching Steel: Techniques, Benefits, and Applications

In the world of metal fabrication, innovative techniques play a vital role in achieving precision and durability. One such advanced technique is deep etching steel, which has revolutionized the way we approach engraving and designing various metal products. In this article, we will delve into the nuances of deep etching steel, examining its process, benefits, and myriad applications within different industries.

What is Deep Etching Steel?

Deep etching steel is a method that involves the removal of material from the surface of steel using chemical, thermal, or mechanical means. This technique creates intricate designs, patterns, or images on the metal surface, making it a popular choice among artists, designers, and manufacturers. Unlike shallow etching, deep etching allows for a more pronounced design, enhancing both the aesthetic and functional properties of the steel.

The Process of Deep Etching Steel

The process of deep etching steel typically involves several key stages:

- Design Creation: The first step in deep etching is creating a design. This often involves the use of CAD (Computer-Aided Design) software to ensure precision and accuracy.

- Surface Preparation: The steel surface must be cleaned and prepped to remove any contaminants. This may include sanding, washing, or applying a chemical cleaner.

- Masking: A coating is applied to protect the areas that will not be etched. This mask can be made from various materials depending on the etching method.

- Etching: The actual etching can be performed using a range of methods:

- Chemical Etching: A chemical solution is applied to the exposed areas, reacting with the steel to create the design.

- Laser Etching: A laser beam precisely removes material from the surface, allowing for highly intricate designs.

- Electrolytic Etching: This technique uses an electrolytic solution and electrical current to etch the designs onto the steel.

- Finishing: After etching, the piece is often finished with additional cleaning, polishing, or coating to enhance its appearance and durability.

Benefits of Deep Etching Steel

Deep etching steel offers numerous advantages that make it an invaluable technique in metal fabrication:

- Enhanced Aesthetics: One of the most significant benefits is the ability to create visually stunning designs that are both intricate and unique.

- Durability: Deep etching increases the durability of the designs. Unlike surface engravings, deep etching is less prone to wear and tear.

- Versatility: This method can be used on various types of steel and other metals, allowing for widespread application across different industries.

- Precision: The deep etching process can achieve high levels of precision, making it ideal for detailed artwork, logos, and custom designs.

- Chemical Resistance: Deep etched steel often exhibits improved resistance to rust and corrosion, especially when adequately coated.

Applications of Deep Etching Steel

The applications of deep etching steel are vast and continually expanding. Here are some prominent sectors utilizing this technique:

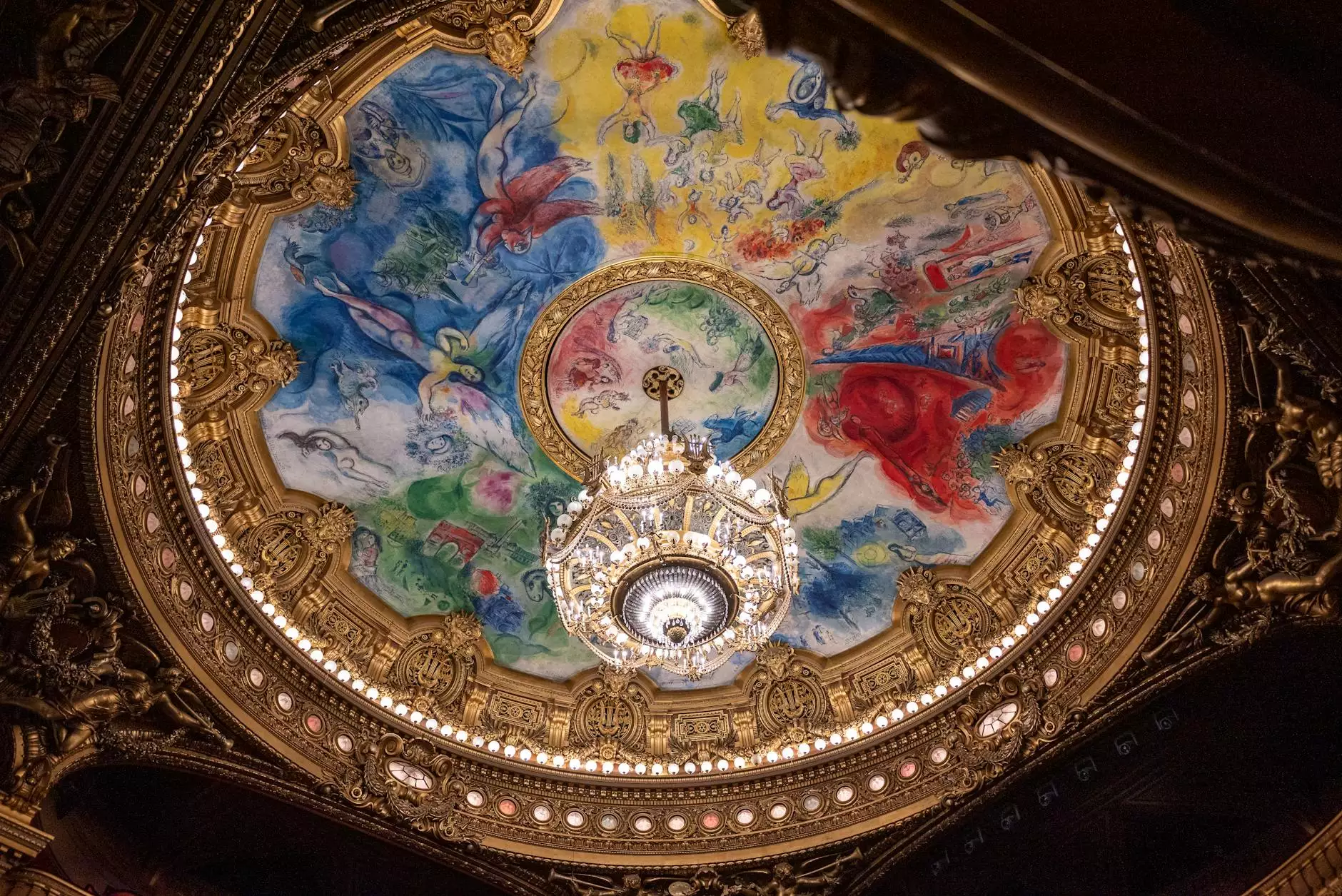

1. Art and Decor

Artists frequently employ deep etching to create metal sculptures, wall art, and decorative panels. The depth of the etching adds layers of texture and visual interest, making each piece a unique work of art.

2. Industrial Use

In manufacturing, deep etching is used to create labels, signs, and control panels. The durability and clarity of the designs make them ideal for high-use environments.

3. Architecture

Many architectural projects integrate deep etched steel for facades, railings, and interior elements, providing both aesthetic appeal and structural integrity.

4. Automotive Sector

Deep etching is used to customize components like emblems, interior trim pieces, and even functional parts, allowing manufacturers to provide personalized options for consumers.

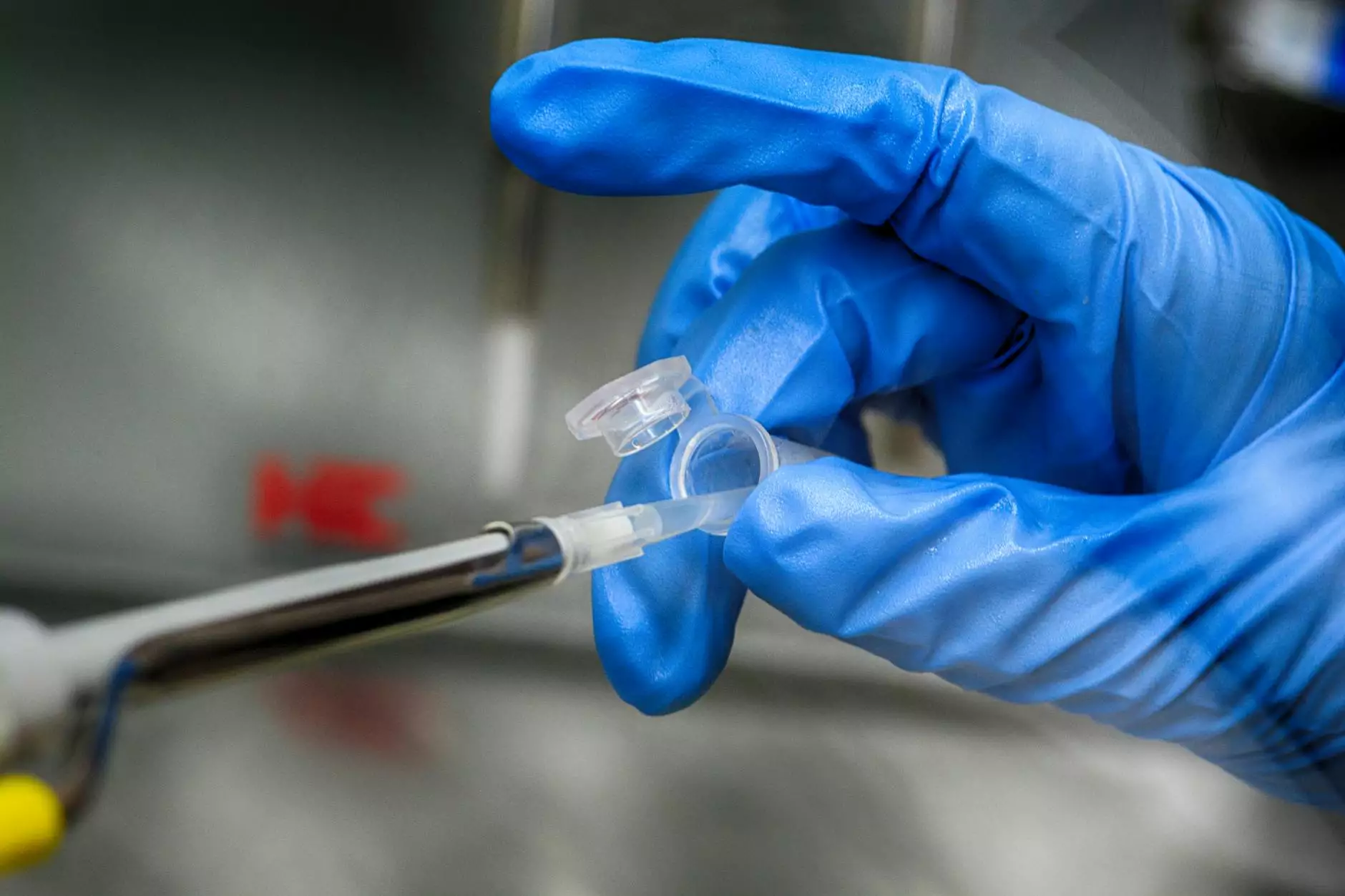

5. Medical and Laboratory Equipment

In the medical field, deep etched surfaces are crucial for labeling equipment and devices. The precision of the etching ensures clear communication of important information.

Choosing a Deep Etching Steel Service Provider

Selecting the right service provider for deep etching steel is critical. Here are some factors to consider when making your choice:

- Experience: Look for a provider with a proven track record in deep etching and metal fabrication.

- Quality of Work: Review their portfolio to assess the quality and creativity of their previous projects.

- Technology: Ensure they use advanced technology and techniques, such as laser etching or chemical processes, for optimal results.

- Customer Service: Choose a company that values communication and can further assist with design modifications or suggestions.

- Material Selection: Verify the types of steel and metals they work with to ensure compatibility with your project needs.

Deep Etching Steel vs. Other Etching Methods

When considering the best technique for engraving metals, it's essential to understand how deep etching compares with other methods:

1. Surface Etching

Surface etching involves the removal of a minimal amount of material, resulting in a design that is not as pronounced as deep etching. While it is less time-consuming, it may not offer the same level of durability or visual depth.

2. Traditional Engraving

Traditional engraving can be labor-intensive and may not achieve the intricate details that deep etching provides. However, it offers a classic aesthetic that some prefer for specific applications.

3. Chemical Mill Etching

This method uses acid to remove material but does not typically allow for the same depth of design as deep etching, making it less suitable for highly detailed projects.

Environmental Considerations

As industries increasingly focus on sustainability, many deep etching steel providers are adopting eco-friendly practices, such as:

- Utilizing non-toxic chemicals for the etching process.

- Implementing recycling programs for scrap metal.

- Employing energy-efficient machinery and processes.

By choosing a provider committed to environmental responsibility, businesses can align their values with sustainable practices while still benefiting from high-quality deep etching services.

Future Trends in Deep Etching Steel

As technology advances, the future of deep etching steel holds exciting possibilities. Emerging trends include:

- Integration with AI: Enhanced design software that utilizes artificial intelligence to optimize patterns and efficiency.

- 3D Etching: Moving beyond traditional 2D designs, the industry may see a rise in 3D etching techniques for more complex designs.

- Sustainability Measures: Continued emphasis on eco-friendly processes, particularly the use of biodegradable chemicals.

Conclusion

Deep etching steel is a transformative technique that empowers artists, manufacturers, and designers to push the boundaries of metal fabrication. With its extensive range of applications, benefits, and future prospects, deep etching has firmly established itself as a crucial method in today’s industrial landscape. By understanding its techniques and applications, businesses can leverage deep etching steel to enhance the quality and aesthetics of their products, ensuring they remain competitive and innovative in an ever-evolving marketplace.

For those interested in utilizing deep etching steel for their projects, exploring services like Goldecosteel.com can provide valuable insights into high-quality metal fabrication solutions tailored to your needs.